WD-40 Specialist® Penetrant Estimated to Save Wind Farm Thousands of Dollars

WD-40 Specialist® Penetrant Estimated to Save Wind Farm Thousands of Dollars

<< BackRead the full case study here.

Customer Challenge

Wind farms are large-scale energy installations that harness power from the wind to produce electricity.

Significant focus is placed on optimizing the layout and turbine technology to generate power more efficiently, while ensuring safety for workers and nearby communities.

Central to this process are the turbines themselves, equipped with blades, towers, and gearboxes that must withstand strong gusts and turbulent weather.

Over time, exposure to harsh conditions can cause wear, so regular maintenance is vital to keep turbines spinning

effectively and prevent costly breakdowns. If key components become corroded or damaged, they risk reduced performance or even turbine failure, which could lead to energy losses.

We supplied a wind farm operator with a complimentary sample of WD-40 Specialist Penetrant for evaluation and then interviewed its operations service manager about the results.

WD-40® Brand Solution

Customer-Reported Results

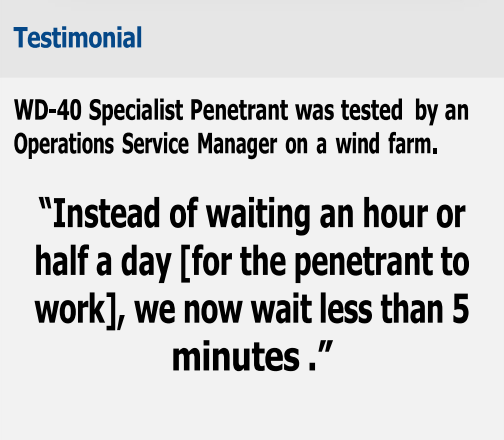

Due to the importance of quickly freeing stuck key shafts on motors and loosening high-torque bolts (Ex: yaw drive bolts) for regular maintenance, the wind farm’s operations service manager tested WD-40 Specialist Penetrant. It was reported that WD-40 Penetrant penetrated rusted, seized parts significantly faster than the previously used competing product.

An added benefit noted was the WD-40 Specialist Penetrant’s lower odor, which allows technicians to apply the product without leaving access doors open or stepping away for ventilation. This results in a more comfortable working environment, especially when working on components that require frequent removal. Because of these reported advantages—faster action, reduced odor, and overall lower product usage—the wind farm converted tom WD-40 Specialist Penetrant.

By converting to WD-40 Penetrant, this location is estimated to save approximately 192 maintenance hours annually, valued at $16,320 in savings. This in turn resulted in a safer, more efficient wind farm facility.

FEATURED PRODUCTS

WANT TO GET MORE TIPS AND TRICKS?

SUBSCRIBE TO THE NEWSLETTER